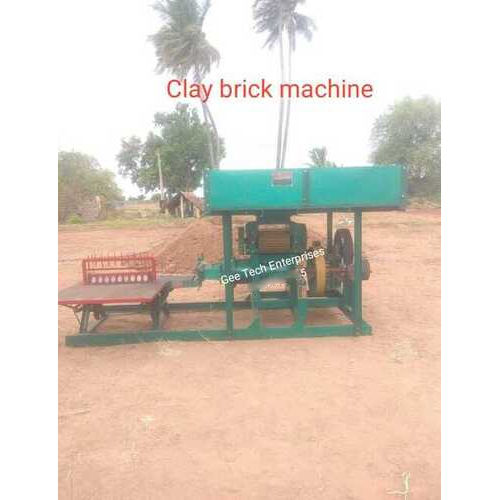

High Speed Extruder for Clay Brick Making Machine

High Speed Extruder for Clay Brick Making Machine Specification

- Product Type

- Brick Extruder

- General Use

- Manufacturing of clay bricks

- Material

- Heavy-duty Alloy Steel

- Capacity

- 8,000-10,000 bricks/hour

- Weight (kg)

- 6500 kg

- Type

- High Speed Extruder

- Computerized

- No

- Automatic

- Yes

- PLC Control

- Optional

- Method

- Extrusion

- Vibration Type

- Mechanical Vibration

- Vibration Frequency

- High Frequency

- Maximum Pressure

- 16-25 MPa

- Machine Power

- 55 kW

- Voltage

- 380V / 50Hz

- Dimension (L*W*H)

- 5200 x 1200 x 1800 mm

- Pallet Size

- No pallet required

- Minimum Height

- 40 mm

- Maximum Height

- 200 mm

- Number of Bricks

- Up to 8000 bricks/hour

- Feature

- High speed, energy saving, robust structure

- Color

- Metallic Grey

- Safety Features

- Overload protection, emergency stop switch

- Main Drive

- Helical gear drive

- Frame Structure

- High tensile welded frame

- Extruder Shaft Speed

- 40-120 rpm adjustable

- Lubrication System

- Centralized automatic lubrication

- Feeding System

- Automatic Clay Feeder

- Cooling System

- Water-cooled

- Noise Level

- <80 dB

- Maintenance Requirement

- Low maintenance

- Brick Size Range

- Standard and custom sizes

- Motor Type

- Three-phase induction motor

- Control Panel

- Digital touch controller

- Brick Mould Type

- Customizable mould

High Speed Extruder for Clay Brick Making Machine Trade Information

- Minimum Order Quantity

- 1` , , Unit

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 15 Days

- Main Domestic Market

- All India

About High Speed Extruder for Clay Brick Making Machine

Buy Online the High Speed Extruder for Clay Brick Making Machine and experience grandiose efficiency in brick production. Featuring a top-notch automatic clay feeder, three-phase induction motor, water-cooled system, and digital touch controller, this machine is engineered for incomparable performance. Jump on advanced extrusion with adjustable shaft speeds (40-120 rpm), robust centralized lubrication, and overload protection for maximum safety. With its heavy-duty alloy steel structure and capacity of up to 10,000 bricks/hour, this high-speed extruder sets an unrivaled standard for manufacturers and suppliers across India. Upgrade your fabrication process now.

Advantage & Commercial Usage of High Speed Extruder

This high speed extruder delivers premium energy saving and robust production, making it ideal for manufacturers aiming for high output and reliable performance. Its automatic feeding system and customizable mould settings suit both standard and specialized brick dimensions. Specifically designed for large-scale clay brick fabrication, the machine facilitates swift commercial production, providing fabricators and suppliers a decisive edge in operational efficiency and product uniformity.

Packaging Details, Domestic Market & Certifications

Packaging details ensure a secure freight charge with sturdy protection for every machine. Outlay includes comprehensive delivery options across India's main domestic markets, prioritizing safe transport and installation. Certified to meet industrial standards, the extruder guarantees dependable performance with every shipment. Buyers can rest assured that each unit arrives intact, ready to enhance site operations with its certified reliability and industry-approved functionality.

Advantage & Commercial Usage of High Speed Extruder

This high speed extruder delivers premium energy saving and robust production, making it ideal for manufacturers aiming for high output and reliable performance. Its automatic feeding system and customizable mould settings suit both standard and specialized brick dimensions. Specifically designed for large-scale clay brick fabrication, the machine facilitates swift commercial production, providing fabricators and suppliers a decisive edge in operational efficiency and product uniformity.

Packaging Details, Domestic Market & Certifications

Packaging details ensure a secure freight charge with sturdy protection for every machine. Outlay includes comprehensive delivery options across India's main domestic markets, prioritizing safe transport and installation. Certified to meet industrial standards, the extruder guarantees dependable performance with every shipment. Buyers can rest assured that each unit arrives intact, ready to enhance site operations with its certified reliability and industry-approved functionality.

FAQ's of High Speed Extruder for Clay Brick Making Machine:

Q: How does the automatic clay feeder enhance brick production efficiency?

A: The automatic clay feeder streamlines the brick making process by ensuring a consistent material flow into the extruder. This results in fewer interruptions and a smoother, more efficient operation, allowing for higher output rates and reduced downtime during large-scale manufacturing.Q: What are the primary commercial uses of the High Speed Extruder for Clay Brick Making Machine?

A: This machine is mainly used by brick manufacturers, fabricators, and suppliers for mass production of clay bricks, serving construction projects and brick supply chains requiring top-notch quality and high volume output.Q: When should the lubrication system be serviced?

A: Thanks to its centralized automatic lubrication system, routine maintenance is minimal. It is advised to inspect and top up the lubrication system periodically, as indicated in the machine's maintenance schedule, or whenever the digital controller alerts the operator for servicing.Q: Where is the main domestic market for this extruder?

A: The main domestic market for the High Speed Extruder is India, where its robust design and adaptable features serve regional manufacturers, fabricators, and service providers engaged in clay brick production.Q: What safety features are integrated in the extruder?

A: This extruder includes overload protection and an emergency stop switch, safeguarding users and maintaining operational integrity during both scheduled and unexpected machine operations.Q: How does mechanical vibration and high frequency operation impact brick quality?

A: Mechanical vibration and high frequency operation ensure uniform compacting and shaping, resulting in bricks with superior density, strength, and consistent measurements, even at high production speeds.

- Minimum Order Quantity

- 1` , , Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 15 Days

- Main Domestic Market

- All India

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Clay Brick Making Machine Category

Clay Brick Making Machine

Price 495000.00 INR / Unit

Minimum Order Quantity : 1 Unit

General Use : Industrial

Color : Green

Feature : High Durability

Warranty : 1 Year

GTE-26 Clay Brick Making Machine

Price 450000.00 INR / Unit

Minimum Order Quantity : 1 Unit

General Use : Industrial

Color : Green

Feature : High Durability

Warranty : 1 Year

GTE-37 Clay Brick Making Machine

Price 450000.00 INR / Unit

Minimum Order Quantity : 1 Unit

General Use : Industrial

Color : Green

Feature : High Durability

Warranty : 1 Year

GTE-36 Clay Brick Making Machine

Price 450000.00 INR / Unit

Minimum Order Quantity : 1 Unit

General Use : Industrial

Color : Green

Feature : High Durability

Warranty : 1 Year

Send Inquiry

Send Inquiry Send SMS

Send SMS